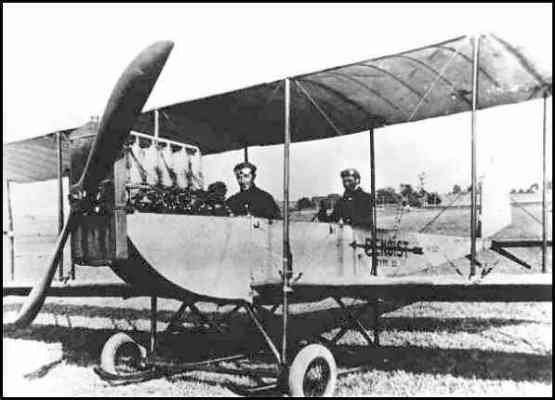

- 11/14/1912 - Creve Couer Lake

It had a Roberts 6 cylinder, 2 cycle engine."

PICTURE FROM THE SMITHSONIAN INSTITUTION .

|

||

|

Walter wrote, "This is the type of plane I made my 1st solo in - 11/14/1912 - Creve Couer Lake It had a Roberts 6 cylinder, 2 cycle engine." PICTURE FROM THE SMITHSONIAN INSTITUTION . |

|

BENOIST TYPE XII, No. 32 At this time, Benoist was only building two types of planes, a pusher biplane with a 75 h.p. Roberts two-cycle engine and a tractor biplane with a Roberts engine. Tractor fuselage was made of plywood and was a box affair about 15 inches square. The pilot sat up above the fuselage with no windshield. When we arrived in St. Louis, Benedict and I had seen a picture of an English pusher biplane, Dehaviland, with a fairly deep fuselage. We asked Tom Benoist if he could duplicate it. The fuselage was linen covered and about two feet deep, so the pilot sat only exposed from the waist up. This was a two passenger tandem plane with a Roberts engine. The fuselage was built in two sections, for shipping. It came apart at a one inch thick plywood bulkhead just aft of the engine. Benoist controls were the one stick in the middle for the control of elevators and ailerons and another stick on the left side for control of the rudder; pull back for left turns, push forward for right turns. The engine was controlled by a foot pedal located in a hole in the bulkhead.between the front and rear seat, using the right foot. The only instrument was an oil guage. The Roberts engine had a carburetor on the right side of the engine which fed gas into a rotary valve extending the full length of the engine. It had ports which fed gas into each cylinder. Gas was mixed with lubricating oil in the tank. Roberts recommended one quart of oil to five gallons of gas, but Tony Jannus found that two quarts of oil to five gallons of gas was better as it prevented the rotary valve from sticking. The carburetor had to be adjusted by hand before each flight. To get R.P.M.'s, the plane was tied down and two men stood out in front of the engine. The one nearest the engine would hold a revolution counter against the end of the propeller shaft. The second man would hold the free hand of the first to keep him from being sucked into the propeller when the engine was revved up. To get thrust or engine pull, the two skids on the landing gear were put on rollers and the wheels were taken off. A pull scale was fastened to the tail skid, the engine revved up full, and a reading taken on the scale.

|